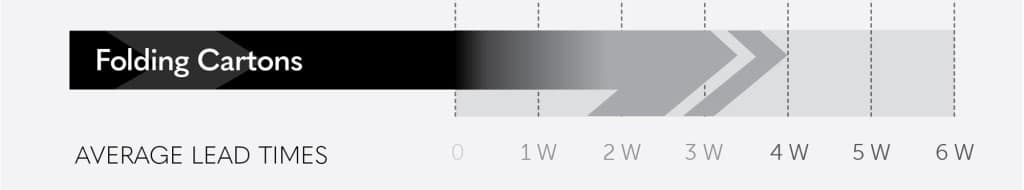

On average, Norka lead times run about 4 weeks from receipt of art and purchase order — we will work with you to accommodate your specific inventory needs to nail down the best date for you. Once established, our vendor-managed inventory system will significantly decrease order lead times.

We would love to get any available die lines, paperboard type and thickness, print specifications, and any other needed finishing details for existing projects. When possible, especially for new projects, it’s ideal for getting the product inside the carton – and we can return anything you send us!

We often consider tooling a long-term investment for us – and would like to remove any obstacles to considering changing suppliers – so whenever possible, we try not to charge for ANY tooling costs! In addition, we do not charge set-up or printing plate costs.

We do not have a minimum order quantity. If needed, we can run as few as 500, especially if this is a pilot project or new product launch. Costs are just significantly higher in the lower quantities. We are happy to discuss the best options for your project needs.

We can produce all kinds of carton structures! Reverse and straight tuck, Tuck Tab/Auto Bottom, Gable Style, 6 corner, Display Caddies, Sealed End, Dispenser Style Displays, Foldelopes (ask us!), Boots, Sleeves – and although not a folding carton, we also do blister cards (face seal, trapped fold over, 2-piece card set).

We will provide you with digital and/or hard copy art proofs and physical samples for your carton design(s) for total structural approvals. We can do this ahead of your purchase order or run this right behind the receipt of the purchase order and still hold to our promised lead times.

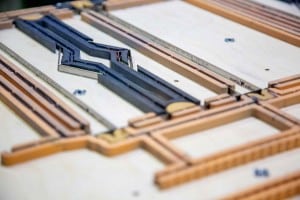

Our unique ability to convert paperboard rolls into sheets allows Norka the highest level of flexibility to create the perfect sheet size for your carton layout, saving time, money AND eliminating waste.

With CMYK, also known as 4 color process, all colors are printed in dots using 4 colors: Cyan, Magenta, Yellow, and Black. The mix or overlapping of these colors creates a full-color wheel spectrum. CMYK achieves virtually endless color combinations by mixing various amounts of these four colors. Only a tiny percentage of the Pantone color library is not achievable by combining CMYK.

Spot color printing uses a color system of solid or premixed colors known as Pantone Matching System (PMS) that is applied only to the area of the assigned color. Norka can print using the CMYK process, spot colors, or a combination of both – it all depends on your graphics and budget. We consult with you to advise which printing method will perform best for your graphics goals.

We will design and prototype any carton style designed for your needs, print, die cut and fold/glue your cartons before preparing your order to hit the road to your facilities. Depending on your carton requirements, we have various coating options: Aqueous gloss or matte, soft touch matte lamination, UV coating, Strikethrough (matte and UV combined), and heat seal coating (for blister cards). Foil stamp and embossing options are always available for any project!

Norka ships all over the United States and into Canada.

We maintain an extensive paperboard inventory to support our industry-leading and FAST production times. We carry: SBS, CCNB, SUS, Kraft 80#. Most of our work is from .016-.024pt, but we can convert as low as 65 lb. up to .030pt.

We LOVE mock-ups – they are an essential part of our design services to ensure you get exactly what you need from our folding cartons or blister cards.